Here introduce

peanut butter production process in details, form raw material selecting to packing.

1. The raw material checking: Make sure there a qualified supplier to provide raw materials, after each batch of peanuts in the factory for sensory test, moisture, impurities, imperfect inspection, after inspection qualified, and then start to use.

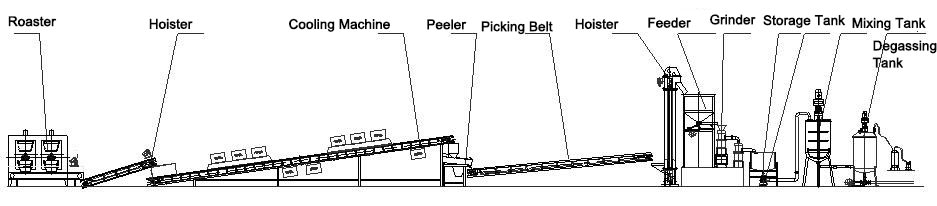

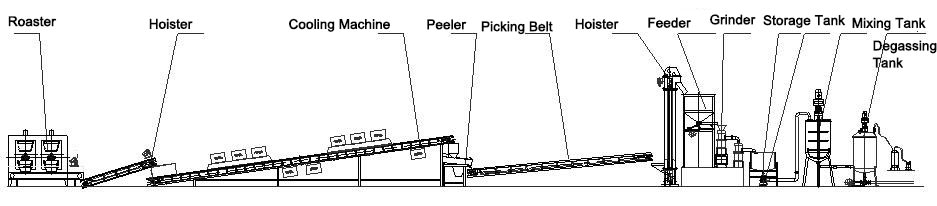

2. Baking: Put qualified peanut in peanuts baking oven, set temperature is about 180-180 ℃, baking for about 20-25 min. After baking peanuts have uniform color, no anxious burnt phenomenon.

3. Cooling: Baked peanuts into the stainless steel cooling machine for cooling in the box.

4. Peeling screening: Peanuts after cooling are sent into peeling machine for peeling.

5. Manual picking: Manually remove foreign bodies, insect damage, mold, anxious burnt grain, impurities, etc from roasted peanuts.

6. Mixing grinding paste: Put the qualified peanuts in the grinding machine for the first salt grinding coarse grinding, ground into a medium fineness 100 mesh, then add stabilizer and related accessories, in mixing pot, put the peanut butter mix and heat to 100-110 ℃ for high-temperature sterilization. Again on the second milling, grinding mill into 200 mesh fine smooth finished product.

7. Filling: Fill the finished product of peanut butter into the customer designated packing, quantitative packaging.

8. Packing: Products after inspection qualified products use labeled packaging warehousing.

9. The finished product inspection: each batch of products before they go out, should through factory inspection.

The contents of factory inspection includes sensory, moisture, fat, protein, net content, the total number of colonies and packaging, labels, marks and inspection with certificate rear can leave the factory.

Jul 25,2017