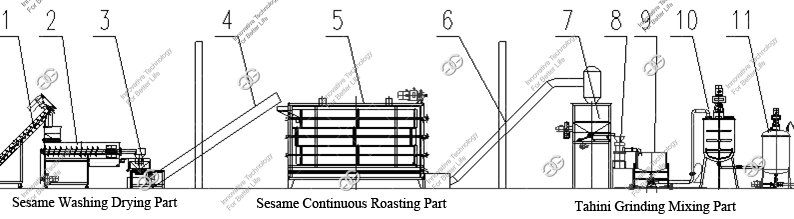

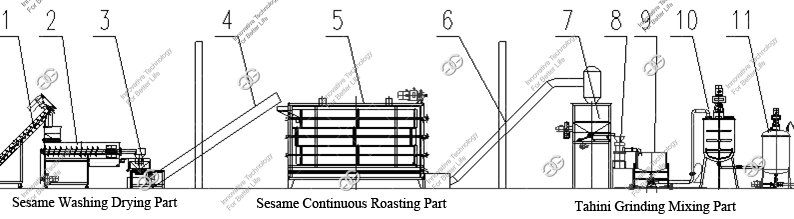

This sesame tahini production line combines domestic and foreign advanced technology with customer demand. This tahini roduction line consists of feed elevator, continuous cleaner and dryer machine, continuous roaster, cooling machine, storing and feeding machine, grinding machines, mixing machine, vacuum degassing tank, pump and other spare parts, with high automation, easy-operating, integrated control, stable performance, high product quality etc.

1. Screw Elevator

2. Continuous Cleaning Machine

3. Drying Machine

4. Elevator

5. Continuous Roasting Machine

6. Pneumatic Conveyor

7. Cooling Storage Hopper

8. Combined Grinding Machine

9. Storing Tank

10. Mixing Tank

11. Degassing Tank

Other parts: Paste Pump, Vacuum Pump, Electric Control Cabinet, etc

Aug 07,2017