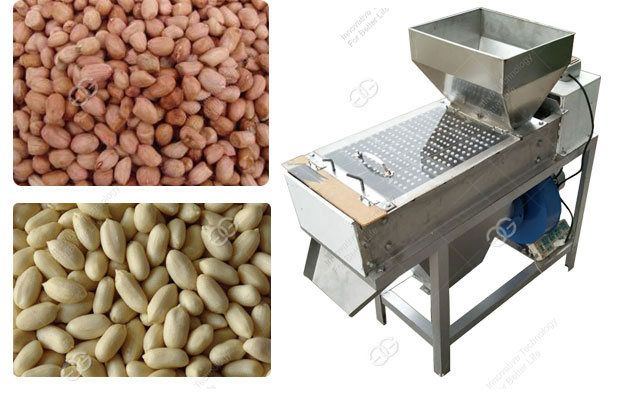

Dry peanut peeling machine, also called roasted peanut peeler, is mainly used for the peeling processing before the production of milky peanuts, peanut butter, peanut milk, or other peanut products. It is an ideal equipment for peeling peanut red skin.

Components of Dry Peanut Peeler Machine

Peanut dry peeling machine consists of power plant, frame, feeding hopper, peeling roller of steel or sand material, suction fan, etc. Power plant includes motor, belt pulley, bearing,etc.

Working principle of Dry Peanut Skin Peeling Machine

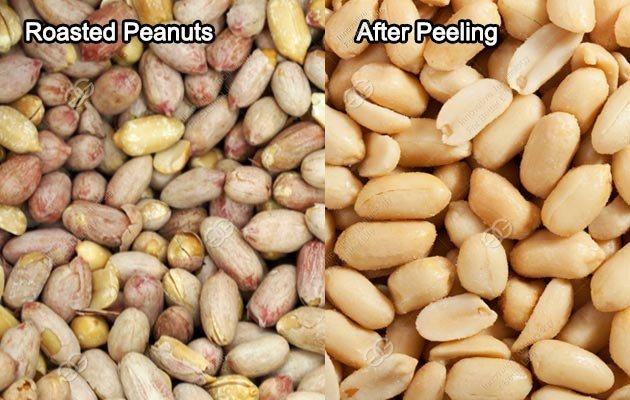

Peanut dry peeling machine is currently the most advanced dry peeling equipment, it adopts the working principle of friction peeling, through the rollers’ different rolling speed and direction. Put peanuts into the feeding hopper, they would automatically enter into the peeling room, there are two groups of friction rollers to peel the peanuts, and then the peanut kernels and skin will be separated by the sieve and sauction system. This peanut peeler is used to peel roasted peanuts, so it is often used with

peanut roaster machine.

Advantages of

Roasted Peanut Peeler Machine

1. Stable performance, safe and reliable;

2. High productivity, good peeling effect, lower broken rate;

3. Reasonable structure, smooth operation, long service life;

4. Large amount production can use more than one set combination;

5. Products quality after peeling achieves export standards.

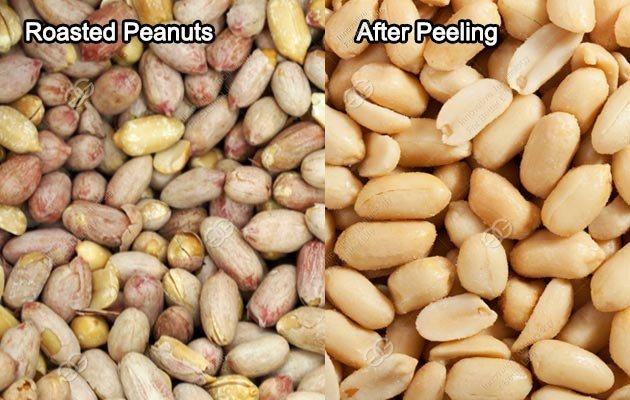

Tips:

Before peanut peeling, ensure that the moisture of peanuts is less than 5%. there are two methods for drying peanuts:

1. You can dry peanuts in the sun until the moisture is less than 5%.

2. You can also choose a peanut roasting machine to make the peanuts suitable for peeling.