This

soaked almond peeler is regarded as the best almond peeling machine, for its’ gentle way of peeling method, can protect the almond kernels from any damage. It mainly apply to the production of almond products such as almond milk, almond biscuits, almond cake, and other almond products.

Features of this almond peeling machine:

peel materials in wet way, almond kernels and almond skin separated automatically, rubber roller of high quality, high peeling rate, low broken rate, no damage to almond kernels, low consumption, no pollution.

Working principle:

This almond peeler machine is equipped with high standards of pure soft rubber roller, adopting friction peeling principle. The soaked almonds feeding into the hopper, the rotating rubber roller will frict the almonds and the soft almond skin will be peeled, the biggest advantage of this wet peeling method is the almond kernels won’t be damaged and keep original taste and color. This machine peels the almond gently just like human hand.

Advantages of this almond peeler:

1.The machine adopts rubber roller peeling method, no damage to the almond kernels.

2.Wet peeling method cause no dust, no pollution.

3.Low energy consumption and high efficiency.

4.Peeling rate is as high as 96%, broken rate is less than 3%.

5.Almond kernels after peeled keep its original taste and color, suitable for most of the almonds production.

6.The almond skin and the kernels can separate automatically during the peeling process.

Application of Wet Almond Peeling Machine

Application of Wet Almond Peeling Machine

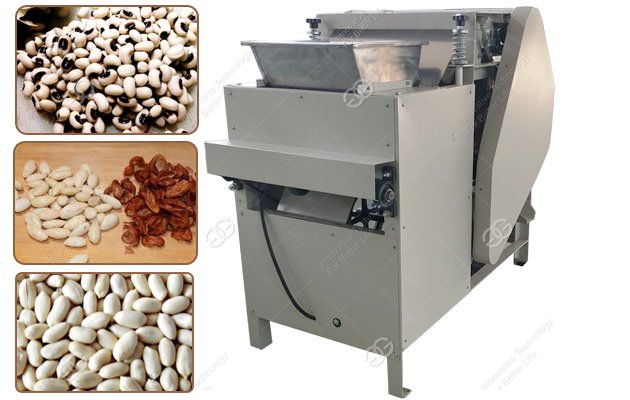

This wet almond peeler is an ideal equipment for almonds peeling, it is widely used in the pre-processing of the production of coated almonds, almond cake, almond candy, almond biscuits, almond milk (cream), almond protein powder and rice pudding, almond butter and canned products. It can also peel other soaked nuts of beans, such as peanuts, soybeans, chick-peas, mung beans, etc.

This soaked almond peeler is regarded as the best almond peeling machine, for its’ gentle way of peeling method, can protect the almond kernels from any damage. It mainly apply to the production of almond products such as almond milk, almond biscuits, almond cake, and other almond products.

This soaked almond peeler is regarded as the best almond peeling machine, for its’ gentle way of peeling method, can protect the almond kernels from any damage. It mainly apply to the production of almond products such as almond milk, almond biscuits, almond cake, and other almond products.